How Intex works, Lets find out?

Intex Technologies, a well known brand for many years in computer peripherals and mobile phones. The brand took the liberty and gave us the privilege to show us the manufacturing scenario of Intex, where the smartphone are assembled, tested and chargers made. As a technology writer, I always have a curiosity to find how smartphones are made, how are they assembled and how they get boxed.

Coming back to Intex Technologies, it is a 20 year old company with a rich history of being leader in Speakers, and feature phones. They somehow know the key to stand in the market and give a tough competition to other Chinese brand in India. The company has reached the turnover of Rs. 6,400 crores in FY 15-16. They also got the achievement of No. 1 Indian mobile Handset brand in Q3 2015 by IDC declaration.

Coming back to Intex Technologies, it is a 20 year old company with a rich history of being leader in Speakers, and feature phones. They somehow know the key to stand in the market and give a tough competition to other Chinese brand in India. The company has reached the turnover of Rs. 6,400 crores in FY 15-16. They also got the achievement of No. 1 Indian mobile Handset brand in Q3 2015 by IDC declaration.

Intex started domestic manufacturing in India since 2004, and currently have five operational facilities

- Jammu- Started in 2004 and Multimedia Speakers are made.

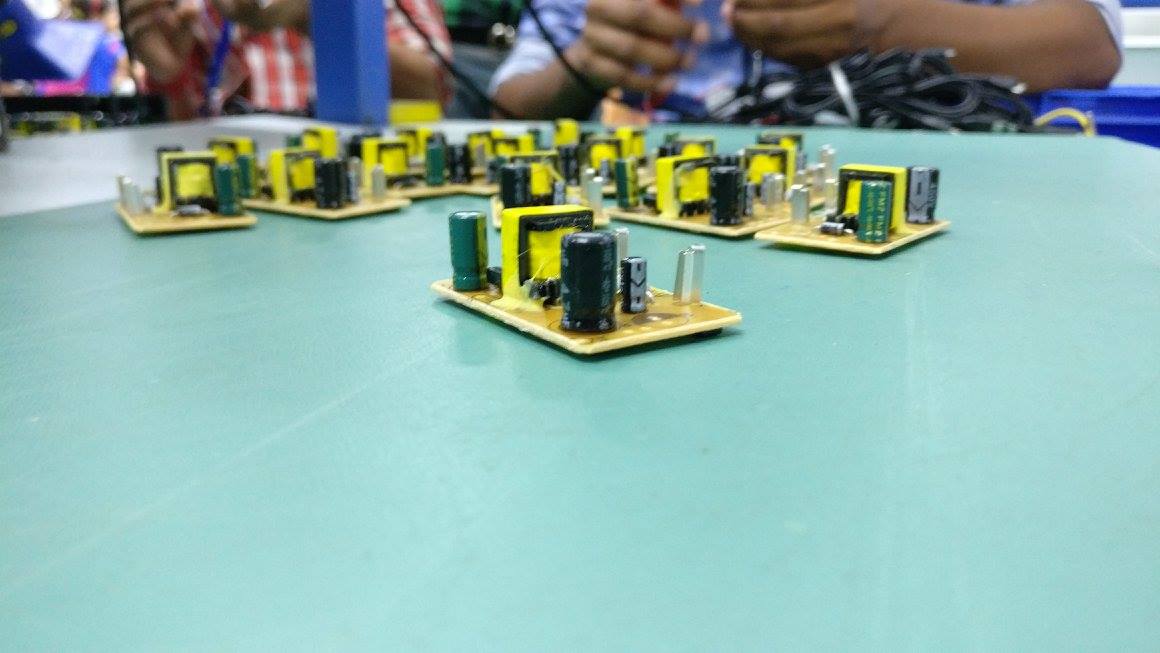

- Baddi – Started in 2010 and Feature phones, LED TV, Batteries and Chargers made.

- Noida (Unit 1) – Started in 2015 and feature phones are made.

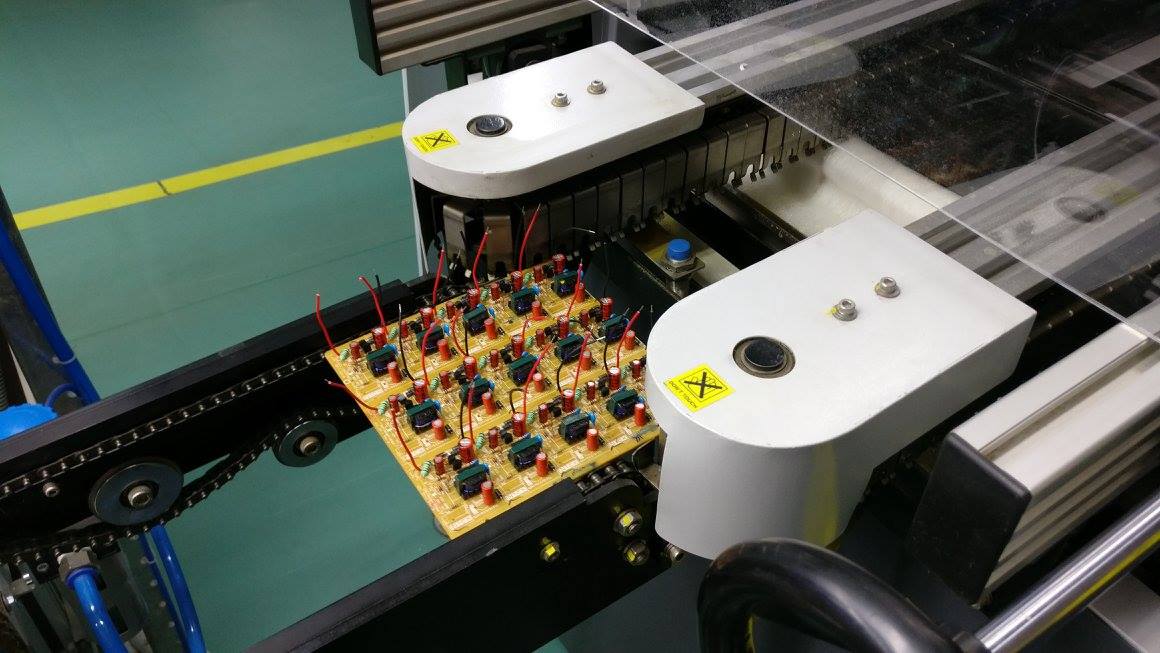

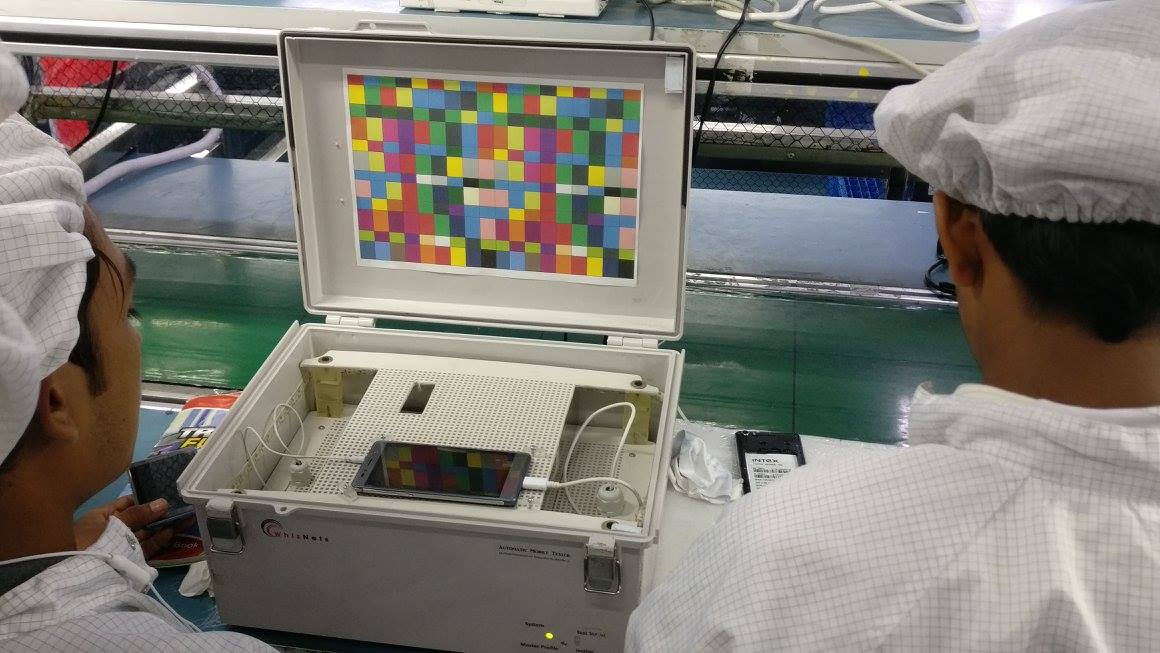

- Noida (Unit 2) – Started in October 2015 and Smartphones are made.

- Noida (Unit 3) – Started in April 2016 and Chargers, batteries are made.

Intex recently entered into Washing Machine market and have over 75 own experience zone for consumers. It has over 5000 employees working in manufacturing plant. It is planning to spread more manufacturing wings in Greater Noida. It has R&D centres in New Delhi and China. Finishing the story with some pictures that were taken inside the manufacturing plant.